Our Commitment: We are committed to continually assessing our waste to landfill across the enterprise, as waste minimization, recycling and reuse is of the utmost importance to our business, the environment and society. We continually monitor and implement best practices for waste recycling and reuse throughout our operations and in partnership with our upstream suppliers and downstream customers. We are also committed to making our packaging more sustainable and engaging with consumers to optimize the management of our products post consumer use, including implementing How2Recycle (H2R) labels across our products.

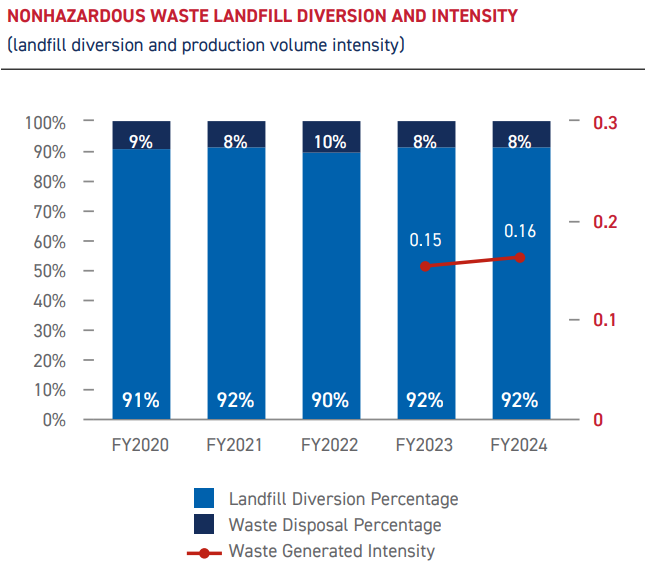

Our Progress: We generated 2% more nonhazardous waste in fiscal year 2024, but were able to recycle 3% more than the previous fiscal year resulting in an overall diversion from landfill rate of 92%. Our Weetabix business has been zero waste since fiscal year 2016, and our two largest businesses, Post Consumer Brands and Foodservice, achieved 95% and 93% landfill diversion, respectively. The inclusion of pet operations results in a waste generated intensity of 0.17 and a decrease to 90% landfill diversion for fiscal year 2024.

- In this Section

- Environmental Data

- GHG Emissions

- Water Stewardship

- Biodiversity and Deforestation

- Sustainable Packaging

- Waste Minimization

- Collective Action

During our fiscal year 2024 data review, we identified inconsistencies in waste definitions and calculations for fiscal years 2020-2022, so the intensity values are not displayed above.

Upcycled Food

Our Commitment: Eliminating food waste across the lifecycle of our products. Feeding people is at the heart of everything we do, so our priority is on donating food for human consumption. As outlined in the Environmental Protection Agency (EPA) Wasted Food Scale, there are additional opportunities to manage food in a beneficial way through an upcycle approach when food cannot be sold in our regular supply chain or donated.

Our Progress: We have a lot to learn in this space and are excited by the opportunities, with the following achievements to date and opportunities to refine our programs:

- Bob Evans Farms launched a Save the Potato Six Sigma project.

- Michael Foods continues to explore how to safely use every part of the egg and potato, including diverting to beneficial byproducts (i.e., animal feed, soil conditioner and other innovative applications). Michael Foods also repurposes manure from egg layer farms.

- The Post Consumer Brands Niagara Falls plant has been zero waste to landfill for nearly a decade by making sure waste is recycled, converted to energy or upcycled as animal feed on local farms. Several other Post Consumer Brands sites are also nearing zero waste, with 2% or less waste going to landfill in fiscal year 2024.

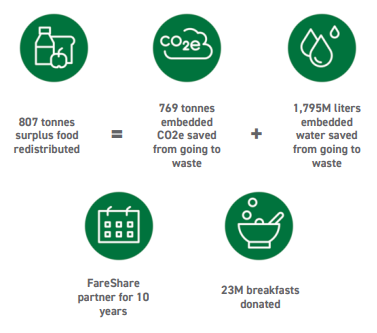

- Weetabix production sites have been zero waste since fiscal year 2016, and Weetabix has also nurtured a 10-year partnership with FareShare, which has helped to redistribute surplus food and has helped community members in need and the environment.

We will also be evaluating relevant product and operational certifications as we build our capacity to understand upcycled food opportunities and incorporate into our products.

Since 2016, Weetabix’s waste streams no longer include Landfill, with waste either being recycled, used as animal feed or sent to “Waste to Energy” incineratio